Welcome To SCC Group !!

Types of Concrete Blocks and their Uses

- Home

- Types of Concrete Blocks and their Uses

23 Dec

- 0 Comments

- By sccgroup

- Blog Grid View Our Blog

- 6 Likes

Types of Concrete Block and their Uses

Construction of any kind begins with basic building blocks. Be it a skyscraper or a small garage- it is vital that the elements used for building it are of top-notch quality. Masonry work is usually done with bricks or stones by fortifying them with mortar.

Some of the main units used in masonry are:

Natural Stones

Clay Bricks

Fly Ash Bricks

Concrete Bricks

Lately, concrete blocks have been builders’ favourite when it comes to masonry work. Normal clay bricks are not used that widely anymore because of their low environment-friendly quotient. By definition, a concrete block is a building block made entirely out of concrete and then bonded with mortar to create a long-lasting building unit. Such concrete blocks are used for building walls, partitions or panelling. Concrete blocks are usually used in the replacement of bricks and stones when they are not readily available. Concrete blocks are either hollow or solid and could be made in a variety of sizes, shapes, and densities- according to the requirement.

Concrete blocks are classified into 2 types:

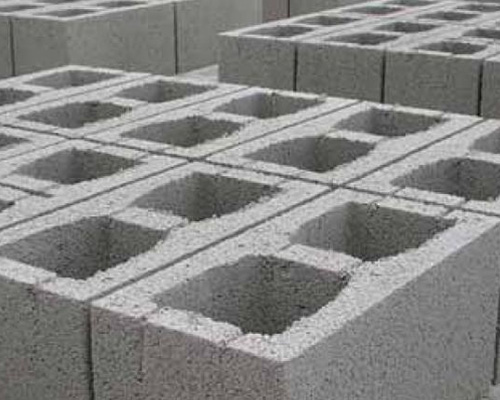

Hollow Concrete Blocks

Hollow concrete blocks are used more often than solid ones because they are easier to carry and handle. Reinforcing hollow concrete blocks is also easier than solid concrete blocks. Solid concrete blocks have specific use cases. They are usually used if the requirement entails fire resistance, noise reduction and absorption, and seclusion or a high level of impenetrability.

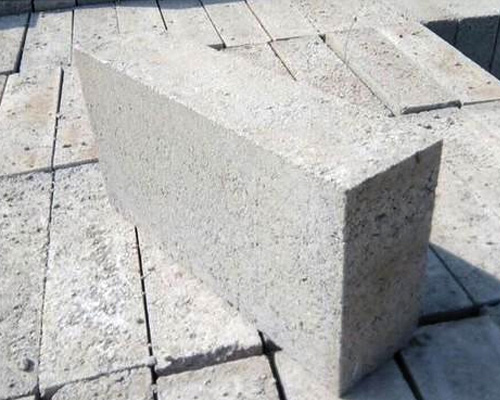

Solid Concrete Blocks

A block that has more than 75% of its mass filled up with concrete is called a concrete block. It is also sometimes known as concrete brick. Whereas, a concrete block that has a solid material content between 50-70% is called a hollow concrete block. Hollow concrete blocks have one or more cavities or they could be hollow from inside but closed from outside. Hollow concrete blocks are further classified into two types- Grade A and Grade B. Grade B hollow concrete blocks are also known as cinder blocks as it is mostly made of cinder aggregate.

There are different types of concrete blocks:

Aerated Autoclaved Concrete Block

Concrete Bricks

Hollow Concrete Blocks

Solid Concrete Blocks

Lintel Blocks

Paving Blocks

Concrete Stretcher Blocks

There are numerous advantages of using Concrete blocks:

✦

Highly resistive to extreme weather conditions like winds, storms, floods, fire, etc.

✦

Hollow concrete blocks require no additional framework for reinforcement

✦

The wall thickness is reduced by the usage of concrete bricks, thus making the carpet area comparatively bigger and making the room appear larger

✦

Better thermal and noise insulation

✦

High resistance to fire

✦

Eco-friendlier than the manufacture of clay bricks, thus protecting agricultural land

✦

Construction is faster, stronger, and more systematic than brick masonry

✦

Higher level of customization and quick turnaround time

✦

Uniform size of concrete blocks can significantly cut down on plaster usage, thus making it a better option economically

Properties of concrete blocks to keep in mind are:

– Dimensions

– Density

– Compressive Strength

– Water Absorption

– Drying Shrinkage

– Moisture Movement

Raw materials to be used for the manufacturing of concrete blocks are cement, aggregate, water, and additives or admixtures. The strength, cost, and texture of any concrete block depend on the type of elements used to manufacture it. The classification of the combined aggregate shall conform to the requirements of Indian Standard Code 383.

Additives or admixtures used in the production of Concrete Masonry Units are:

✦

Water reducing, accelerating, air-entraining and superplasticizers conforming to Indian Standard Code 9103

✦

Waterproofing agents conforming to Indian Standard Code 2645

Where no applicable Indian Standards are available, the additives or admixtures shall be used based on ASTM or British Standard.

Manufacturing of concrete blocks is done in a 5 step process:

– Proportioning

– Mixing

– Compacting

– Curing

– Drying